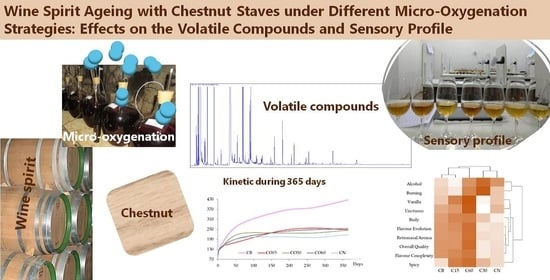

Wine Spirit Ageing with Chestnut Staves under Different Micro-Oxygenation Strategies: Effects on the Volatile Compounds and Sensory Profile

Abstract

:1. Introduction

2. Materials and Methods

2.1. Reagents

2.2. Wine Spirit Samples and Experimental Design

- CB—250 L wooden barrel of chestnut wood;

- CO15—50 L glass demijohns with chestnut staves and micro-oxygenation with a flow rate of 2 mL/L/month during the first 15 days followed by 0.6 mL/L/month until 365 days;

- CO30—50 L demijohns with chestnut staves and submitted to a micro-oxygenation with a flow rate of 2 mL/L/month during the first 30 days followed by 0.6 mL/L/month until 365 days;

- CO60—50 L glass demijohns with chestnut staves and submitted to a micro-oxygenation with a flow rate of 2 mL/L/month during the first 60 days followed by 0.6 mL/L/month until 365 days;

- CN—50 L demijohns with chestnut staves and nitrogen application with a flow rate of 20 mL/L/month (nitrogen modality).

2.3. Analysis of Odorant Compounds of Wine Spirits

2.3.1. Quantification of Major Volatile Compounds by GC-FID

2.3.2. Quantification of Minor Volatile Compounds by GC-FID

2.3.3. Analysis by GC/MS

2.4. Sensory Evaluation of Wine Spirits

2.5. Statistical Analysis of Data

3. Results and Discussion

3.1. Evolution of Target Volatile Compounds over the Ageing Experiment

3.2. Odorant Compounds of Aged Wine Spirits

3.3. Sensory Results

3.4. Multidimensional Approach of the Similarity/Dissimilarity of Aged Wine Spirit Samples

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bertrand, A. Armagnac and Wine-Spirits. In Fermented Beverage Production; Lea, A.G.H., Piggot, J., Eds.; Springer US: Boston, MA, USA, 2003; pp. 213–238. [Google Scholar] [CrossRef]

- Canas, S.; Caldeira, I.; Belchior, A.P.; Spranger, M.I.; Clímaco, M.C.; Bruno-de-Sousa, R. Chestnut Wooden Barrels for the Ageing of Wine Spirits. International Organisation of Vine and Wine. 2018. Available online: http://www.oiv.int/en/technical-standards-anddocuments/collective-expertise/spirit-beverages (accessed on 15 April 2021).

- del Alamo-Sanza, M.; Nevares, I. Oak Wine Barrel as an Active Vessel: A Critical Review of Past and Current Knowledge. Crit. Rev. Food Sci. Nutr. 2017, 58, 2711–2726. [Google Scholar] [CrossRef]

- Nishimura, K.; Ohnishi, M.; Masuda, M.; Koga, K.; Matsuyama, R. Reactions of Wood Components during Maturation. In Flavour of Distilled Beverages: Origin and Development; Piggott, J.R., Ed.; Ellis Horwood Limited: West Sussex, UK, 1983; pp. 241–255. [Google Scholar]

- Caldeira, I.; Mateus, A.M.; Belchior, A.P. Flavour and Odour Profile Modifications during the First Five Years of Lourinhã Brandy Maturation on Different Wooden Barrels. Anal. Chim. Acta 2006, 563, 264–273. [Google Scholar] [CrossRef]

- Léauté, R.; Mosedale, J.R.; Mourgues, J.; Puech, J.-L. Barrique et Vieillissement Des Eaux-de-Vie. In Oenologie Fondements Scientifiques et Technologiques; Flanzy, C., Ed.; Tec&Doc: Paris, France, 1998; pp. 1085–1142. [Google Scholar]

- Lurton, L.; Ferrari, G.; Snakkers, G. Cognac: Production and Aromatic Characteristics. In Alcoholic Beverages; Piggot, J.R., Ed.; Woodhead Publishing: Cambridge, UK, 2012; pp. 242–266. [Google Scholar] [CrossRef]

- Caldeira, I.; Anjos, O.; Portal, V.; Belchior, A.P.; Canas, S. Sensory and Chemical Modifications of Wine-Brandy Aged with Chestnut and Oak Wood Fragments in Comparison to Wooden Barrels. Anal. Chim. Acta 2010, 660, 43–52. [Google Scholar] [CrossRef] [PubMed]

- Awad, P.; Athès, V.; Decloux, M.E.; Ferrari, G.; Snakkers, G.; Raguenaud, P.; Giampaoli, P. Evolution of Volatile Compounds during the Distillation of Cognac Spirit. J. Agric. Food Chem. 2017, 65, 7736–7748. [Google Scholar] [CrossRef] [PubMed]

- Caldeira, I.; Santos, R.; Ricardo-Da-Silva, J.M.; Anjos, O.; Mira, H.; Belchior, A.P.; Canas, S. Kinetics of Odorant Compounds in Wine Brandies Aged in Different Systems. Food Chem. 2016, 211, 937–946. [Google Scholar] [CrossRef]

- Caldeira, I.; de Sousa, R.B.; Belchior, A.P.; Clímaco, M.C. A Sensory and Chemical Approach to the Aroma of Wooden Aged Lourinhã Wine Brandy. Cienc. Tec. Vitivinic. 2008, 23, 97–110. [Google Scholar]

- Janáčová, A.; Sádecká, J.; Kohajdová, Z.; Špánik, I. The Identification of Aroma-Active Compounds in Slovak Brandies Using GC-Sniffing, GC-MS and Sensory Evaluation. Chromatographia 2008, 67, 113–121. [Google Scholar] [CrossRef]

- Zhao, Y.P.; Wang, L.; Li, J.M.; Pei, G.R.; Liu, Q.S. Comparison of Volatile Compounds in Two Brandies Using HS-SPME Coupled with GC-O, GC-MS and Sensory Evaluation. S. Afr. J. Enol. Vitic. 2011, 32, 9–20. [Google Scholar] [CrossRef] [Green Version]

- Puech, J.-L.; Leauté, R.; Clot, G.; Nomdedeu, L.; Mondiés, H. Évolution de Divers Constituants Volatils et Phénoliques Des Eaux-de-Vie de Cognac Au Cours de Leur Vieillissement. Sci. Aliments 1984, 4, 65–80. [Google Scholar]

- Reazin, G.H. Chemical Analysis of Whisky Maturation. In Flavour of Distilled Beverages: Origin and Development; Piggott, J.R., Ed.; Ellis Horwood Limited: West Sussex, UK, 1983; pp. 225–240. [Google Scholar]

- Rodriguez Madrera, R.; Garcia Hevia, A.; Suárez Valles, B. Comparative Study of Two Aging Systems for Cider Brandy Making. Changes in Chemical Composition. LWT Food Sci. Technol. 2013, 54, 513–520. [Google Scholar] [CrossRef]

- Coldea, T.E.; Socaciu, C.; Mudura, E.; Socaci, S.A.; Ranga, F.; Pop, C.R.; Vriesekoop, F.; Pasqualone, A. Volatile and Phenolic Profiles of Traditional Romanian Apple Brandy after Rapid Ageing with Different Wood Chips. Food Chem. 2020, 320, 126643. [Google Scholar] [CrossRef]

- Rodríguez-Solana, R.; Rodríguez-Freigedo, S.; Salgado, J.M.; Domínguez, J.M.; Cortés-Diéguez, S. Optimisation of Accelerated Ageing of Grape Marc Distillate on a Micro-Scale Process Using a Box–Benhken Design: Influence of Oak Origin, Fragment Size and Toast Level on the Composition of the Final Product. Aust. J. Grape Wine Res. 2017, 23, 5–14. [Google Scholar] [CrossRef] [Green Version]

- Taloumi, T.; Makris, D. Accelerated Aging of the Traditional Greek Distillate Tsipouro Using Wooden Chips. Part I: Effect of Static Maceration vs. Ultrasonication on the Polyphenol Extraction and Antioxidant Activity. Beverages 2017, 3, 5. [Google Scholar] [CrossRef] [Green Version]

- Quesada Granados, J.; Merelo Guervós, J.J.; Oliveras López, M.J.; González Peñalver, J.; Olalla Herrera, M.; Blanca Herrera, R.; López Martinez, M.C. Application of Artificial Aging Techniques to Samples of Rum and Comparison with Traditionally Aged Rums by Analysis with Artificial Neural Nets. J. Agric. Food Chem. 2002, 50, 1470–1477. [Google Scholar] [CrossRef]

- Bortoletto, A.M.; Alcarde, A.R. Aging Marker Profile in Cachaça Is Influenced by Toasted Oak Chips. J. Inst. Brew. 2015, 121, 70–77. [Google Scholar] [CrossRef]

- Canas, S.; Caldeira, I.; Belchior, A.P. Comparison of Alternative Systems for the Ageing of Wine Brandy. Wood Shape and Wood Botanical Species Effect. Cienc. Tec. Vitivinic. 2009, 24, 91–99. [Google Scholar]

- Cruz, S.; Canas, S.; Belchior, A.P. Effect of Ageing System and Time on the Quality of Wine Brandy Aged at Industrial-Scale. Cienc. Tec. Vitivinic. 2012, 27, 83–93. [Google Scholar]

- Canas, S.; Danalache, F.; Anjos, O.; Fernandes, T.A.; Caldeira, I.; Santos, N.; Fargeton, L.; Boissier, B.; Catarino, S. Behaviour of Low Molecular Weight Compounds, Iron and Copper of Wine Spirit Aged with Chestnut Staves under Different Levels of Micro-Oxygenation. Molecules 2020, 25, 5266. [Google Scholar] [CrossRef]

- Granja-Soares, J.; Roque, R.; Cabrita, M.J.; Anjos, O.; Belchior, A.P.; Caldeira, I.; Canas, S. Effect of Innovative Technology Using Staves and Micro-Oxygenation on the Odorant and Sensory Profile of Aged Wine Spirit. Food Chem. 2020, 333, 127450. [Google Scholar] [CrossRef]

- Luís, A.C.P.M.N.; Mota, D.; Anjos, O.; Caldeira, I. Single-Laboratory Validation of Determination of Acetaldehyde, Ethyl Acetate, Methanol and Fusel Alcohols in Wine Spirits, Brandies and Grape Marc Spirits Using GC-FID. Cienc. Tec. Vitivinic. 2011, 26, 69–76. [Google Scholar]

- Caldeira, I.; Pereira, R.; Clímaco, M.C.; Belchior, A.P.; Bruno de Sousa, R. Improved Method for Extraction of Aroma Compounds in Aged Brandies and Aqueous Alcoholic Wood Extracts Using Ultrasound. Anal. Chim. Acta 2004, 513, 125–134. [Google Scholar] [CrossRef]

- ISO 3591:1977. Sensory Analysis-Wine-Tasting Glass. This Standard Was Last Reviewed and Confirmed in 2016; International Organization for Standardization: Geneva, Switzerland, 2016.

- Macfie, H.J.M.; Bratchell, N.; Greenhoff, H.; Vallis, L.V. Designs to Balance the Effect of Order of Presentation and First-Order Carry-over Effects in Hall Tests. J. Sens. Stud. 1989, 4, 129–148. [Google Scholar] [CrossRef]

- Mateo, J.; Jiménez, M. Monoterpenes in Grape Juice and Wines. J. Chromatogr. A 2000, 881, 557–567. [Google Scholar] [CrossRef]

- Lurton, L.; Snakkers, G.; Roulland, C.; Galy, B.; Versavaud, A. Influence of the Fermentation Yeast Strain on the Composition of Wine Spirits. J. Sci. Food Agric. 1995, 67, 485–491. [Google Scholar] [CrossRef]

- Lillo, M.P.Y.; Agosin, E.; Belancic, A.; Latrille, E. Chemical Markers for Tracking the Sensory Contribution of Production Stages in Muscat Wine Distillates. J. Food Sci. 2005, 70, s432–s441. [Google Scholar] [CrossRef]

- Skouroumounis, G.K.; Sefton, M.A. Acid-Catalyzed Hydrolysis of Alcohols and Their β-D-Glucopyranosides. J. Agric. Food Chem. 2000, 48, 2033–2039. [Google Scholar] [CrossRef]

- Strauss, C.R.; Wilson, B.; Williams, P.J. Novel Monoterpene Diols and Diol Glycosides in Vitis Vinifera Grapes. J. Agric. Food Chem. 1988, 36, 569–573. [Google Scholar] [CrossRef]

- Black, C.A.; Parker, M.; Siebert, T.E.; Capone, D.L.; Francis, I.L. Terpenoids and Their Role in Wine Flavour: Recent Advances. Aust. J. Grape Wine Res. 2015, 21, 582–600. [Google Scholar] [CrossRef]

- Slaghenaufi, D.; Ugliano, M. Norisoprenoids, Sesquiterpenes and Terpenoids Content of Valpolicella Wines during Aging: Investigating Aroma Potential in Relationship to Evolution of Tobacco and Balsamic Aroma in Aged Wine. Front. Chem. 2018, 6. [Google Scholar] [CrossRef] [Green Version]

- Tsakiris, A.; Kallithraka, S.; Kourkoutas, Y. Brandy and Cognac: Manufacture and Chemical Composition. In Encyclopedia of Food and Health; Elsevier: Amsterdam, The Netherlands, 2016; pp. 462–468. [Google Scholar] [CrossRef]

- Baron, M.; Prusova, B.; Tomaskova, L.; Kumsta, M.; Sochor, J. Terpene Content of Wine from the Aromatic Grape Variety ‘Irsai Oliver’ (Vitis Vinifera L.) Depends on Maceration Time. Open Life Sci. 2017, 12, 42–50. [Google Scholar] [CrossRef]

- Flemming, I. Molecular Orbitals and Organic Chemical Reactions; John Wiley and Sons, Ltd.: Hoboken, NJ, USA, 2009. [Google Scholar]

- Fengel, D.; Wegener, G. Wood-Chemistry, Ultrastructure, Reactions, 2nd ed.; Walter de Gruyter: Berlin, Germany, 1989. [Google Scholar]

- Schwarz, M.; Rodríguez, M.C.; Guillén, D.A.; Barroso, C.G. Analytical Characterisation of a Brandy de Jerez during Its Ageing. Eur. Food Res. Technol. 2011, 232, 813–819. [Google Scholar] [CrossRef]

- Valcárcel-Muñoz, M.J.; Guerrero-Chanivet, M.; García-Moreno, M.V.; Rodríguez-Dodero, M.C.; Guillén-Sánchez, D.A. Comparative Evaluation of Brandy de Jerez Aged in American Oak Barrels with Different Times of Use. Foods 2021, 10, 288. [Google Scholar] [CrossRef] [PubMed]

- Tsakiris, A.; Kallithraka, S.; Kourkoutas, Y. Grape Brandy Production, Composition and Sensory Evaluation. J. Sci. Food Agric. 2014, 94, 404–414. [Google Scholar] [CrossRef] [PubMed]

- Bezhuashvili, M.G.; Eradze, N.N.; Mudjiri, L.A. Formation of Pyrogallol Ether during Oxidative Destruction of Oak Lignine with Air Oxygen. Appl. Biochem. Microbiol. 2000, 36, 33–35. [Google Scholar] [CrossRef]

- Viriot, C.; Scalbert, A.; Lapierre, C.; Moutounet, M. Ellagitannins and Lignins in Aging of Spirits in Oak Barrels. J. Agric. Food Chem. 1993, 41, 1872–1879. [Google Scholar] [CrossRef]

- Pisarnitskii, A.F.; Askenderov, K.A. Study of Alcohol-Soluble Lignin in Cognac Spirits. Appl. Biochem. Microbiol. 2008, 44, 652–656. [Google Scholar] [CrossRef]

- Martínez-Gil, A.; del Alamo-Sanza, M.; Sánchez-Gómez, R.; Nevares, I. Different Woods in Cooperage for Oenology: A Review. Beverages 2018, 4, 94. [Google Scholar] [CrossRef] [Green Version]

- Peinado, R.A.; Moreno, J.; Bueno, J.E.; Moreno, J.A.; Mauricio, J.C. Comparative Study of Aromatic Compounds in Two Young White Wines Subjected to Pre-Fermentative Cryomaceration. Food Chem. 2004, 84, 585–590. [Google Scholar] [CrossRef]

- Piornos, J.A.; Delgado, A.; de La Burgade, R.C.J.; Methven, L.; Balagiannis, D.P.; Koussissi, E.; Brouwer, E.; Parker, J.K. Orthonasal and Retronasal Detection Thresholds of 26 Aroma Compounds in a Model Alcohol-Free Beer: Effect of Threshold Calculation Method. Food Res. Int. 2019, 123, 317–326. [Google Scholar] [CrossRef]

- Culleré, L.; Escudero, A.; Cacho, J.; Ferreira, V. Gas Chromatography-Olfactometry and Chemical Quantitative Study of the Aroma of Six Premium Quality Spanish Aged Red Wines. J. Agric. Food Chem. 2004, 52, 1653–1660. [Google Scholar] [CrossRef]

- Roussey, C.; Colin, J.; Teissier du Cros, R.; Casalinho, J.; Perré, P. In-Situ Monitoring of Wine Volume, Barrel Mass, Ullage Pressure and Dissolved Oxygen for a Better Understanding of Wine-Barrel-Cellar Interactions. J. Food Eng. 2021, 291, 110233. [Google Scholar] [CrossRef]

- Canas, S.; Belchior, A.P.; Mateus, A.M.; Spranger, M.I.; Bruno De Sousa, R. Kinetics of Impregnation/Evaporation and Release of Phenolic Compounds from Wood to Brandy in Experimental Model. Ciência e Técnica Vitivinícola 2002, 17, 1–14. [Google Scholar]

- Krebs, G.; Gastl, M.; Becker, T. Chemometric Modeling of Palate Fullness in Lager Beers. Food Chem. 2021, 342, 128253. [Google Scholar] [CrossRef] [PubMed]

- Gawel, R.; Smith, P.A.; Waters, E.J. Influence of Polysaccharides on the Taste and Mouthfeel of White Wine. Aust. J. Grape Wine Res. 2016, 22, 350–357. [Google Scholar] [CrossRef]

| Ageing Time (days) | |||||||

|---|---|---|---|---|---|---|---|

| 0 | 8 | 60 | 180 | 270 | 365 | ||

| Significance level | - | ns | ns | ns | ns | 0.008 | |

| Linalool (mg/L)  | CB | 0.31 | 0.30 | 0.27 | 0.22 | 0.20 | 0.14 a |

| CO15 | 0.28 | 0.27 | 0.24 | 0.21 | 0.17 a | ||

| CO30 | 0.29 | 0.26 | 0.26 | 0.23 | 0.25 b | ||

| CO60 | 0.27 | 0.24 | 0.23 | 0.19 | 0.25 b | ||

| CN | 0.28 | 0.26 | 0.24 | 0.20 | 0.16 a | ||

| Significance level | - | ns | ns | 0.016 | 0.001 | 0.013 | |

| Acetaldehyde (mg/L)  | CB | 28.90 | 40.03 | 61.05 | 58.82 a | 43.99 a | 56.64 a,b |

| CO15 | 40.90 | 51.59 | 64.84 b | 59.18 b | 66.01 c | ||

| CO30 | 43.51 | 56.75 | 65.66 b | 57.39 b | 60.09 b,c | ||

| CO60 | 46.99 | 67.93 | 66.20 b | 56.80 b | 59.68 b | ||

| CN | 43.51 | 61.05 | 58.91 a | 43.10 a | 51.43 a | ||

| Significance level | - | 0.018 | 0.002 | 0.000 | 0.000 | 0.000 | |

| Acetic acid (mg/L)  | CB | 84.84 | 153.21 b | 278.62 b | 361.03 c | 381.05 c | 427.14 c |

| CO15 | 141.14 a | 177.73 a | 243.14 b | 257.36 b | 246.85 b | ||

| CO30 | 136.65 a | 222.63a,b | 227.29 b | 228.15 a,b | 245.20 b | ||

| CO60 | 141.61 a | 197.79 a,b | 235.89 b | 247.97 b | 254.33 b | ||

| CN | 133.65 a | 195.48 a,b | 205.58 a | 200.83 a | 218.29 a | ||

| Significance level | - | 0.002 | 0.000 | 0.000 | 0.000 | 0.000 | |

| Syringol (mg/L)  | CB | 0.00 | 0.14 a | 0.22 a | 0.24 a | 0.27 a | 0.28 a |

| CO15 | 0.27 b | 1.03 b | 1.46 b | 1.50 b | 1.39 b | ||

| CO30 | 0.25 b | 1.02 b | 1.42 b | 1.37 b | 1.43 b | ||

| CO60 | 0.27 b | 1.04 b | 1.39 b | 1.42 b | 1.48 b | ||

| CN | 0.23 b | 0.93 b | 1.34 b | 1.38 b | 1.30 b | ||

| Odorant Compound | Significance Level | Control | Aged Wine Spirits after 365 Days of Ageing Modality | ||||

|---|---|---|---|---|---|---|---|

| CB | CO15 | CO30 | CO60 | CN | |||

| Isobutyl acetate | 0.002 | 2.36 | 1.81 b | 0.55 a | 0.0 a | 0.0 a | 1.34 b |

| Ethyl hexanoate | 0.009 | 1.20 | 1.89 c | 1.72 b | 1.72 b | 1.80 b,c | 1.58 a |

| Guaiacol | 0.001 | 0.00 | 0.11 a | 0.51 b | 0.45 b | 0.46 b | 0.48 b |

| 4-Methylguaiacol | 0.004 | 0.00 | 0.05 a | 0.31 b | 0.28 b | 0.25 b | 0.28 b |

| Eugenol | 0.021 | 0.00 | 0.33 c | 0.28 a,b | 0.30 b,c | 0.28 a,b | 0.23 a |

| 4-Methylsyringol | 0.000 | 0.00 | 0.36 a | 1.24 c | 1.24 c | 1.26 c | 1.09 b |

| Vanillin | 0.014 | 0.00 | 7.74 b | 7.52 b | 7.14 b | 8.21 b | 4.97 a |

| Acetovanillone | 0.003 | 0.00 | 0.34 a | 0.80 b,c | 0.81 b,c | 0.97 c | 0.77 b |

| Ethyl acetate | 0.003 | 459.88 | 472.54 c | 389.74 b | 374.85 a,b | 382.28 b | 335.22 a |

| Sensory Attribute | Significance Level | Control | Aged Wine Spirits after 365 Days of Ageing Modality | ||||

|---|---|---|---|---|---|---|---|

| CB | CO15 | CO30 | CO60 | CN | |||

| Alcohol | 0.048 | 2.4 | 1.9 a | 1.8 a | 2.3 b | 2.2 a,b | 2.2 a,b |

| Vanilla | 0.010 | 0.0 | 1.9 a,b | 2.3 b,c | 1.6 a | 2.5 c | 1.9 a,b |

| Spicy | 0.009 | 0.0 | 1.6 a | 2.1 b | 1.8 a,b | 2.2 b | 1.6 a |

| Burning | 0.041 | 2.4 | 2.0 a | 1.9 a | 2.5 b | 2.3 a,b | 2.0 a |

| Body | 0.014 | 2.0 | 3.0 b,c | 3.1 b,c | 2.8 a,b | 3.2 c | 2.6 a |

| Unctuous | 0.000 | 1.1 | 2.7 b | 2.8 b | 2.2 a | 3.1 c | 2.6 b |

| Flavor evolution | 0.000 | 1.3 | 3.2 b | 3.3 b | 2.6 a | 3.5 b | 2.7 a |

| Flavor complexity | 0.001 | 1.8 | 3.1 b | 3.2 b | 2.6 a | 3.3 b | 2.7 a |

| Retronasal aroma | 0.002 | 2.4 | 3.3 b | 3.3 b | 2.9 a | 3.6 b | 2.9 a |

| Overall quality | 0.001 | - | 14.5 b,c | 14.6 c | 13.1 a | 15.1 c | 13.6 a,b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Caldeira, I.; Vitória, C.; Anjos, O.; Fernandes, T.A.; Gallardo, E.; Fargeton, L.; Boissier, B.; Catarino, S.; Canas, S. Wine Spirit Ageing with Chestnut Staves under Different Micro-Oxygenation Strategies: Effects on the Volatile Compounds and Sensory Profile. Appl. Sci. 2021, 11, 3991. https://doi.org/10.3390/app11093991

Caldeira I, Vitória C, Anjos O, Fernandes TA, Gallardo E, Fargeton L, Boissier B, Catarino S, Canas S. Wine Spirit Ageing with Chestnut Staves under Different Micro-Oxygenation Strategies: Effects on the Volatile Compounds and Sensory Profile. Applied Sciences. 2021; 11(9):3991. https://doi.org/10.3390/app11093991

Chicago/Turabian StyleCaldeira, Ilda, Cláudia Vitória, Ofélia Anjos, Tiago A. Fernandes, Eugénia Gallardo, Laurent Fargeton, Benjamin Boissier, Sofia Catarino, and Sara Canas. 2021. "Wine Spirit Ageing with Chestnut Staves under Different Micro-Oxygenation Strategies: Effects on the Volatile Compounds and Sensory Profile" Applied Sciences 11, no. 9: 3991. https://doi.org/10.3390/app11093991